Food and Beverages

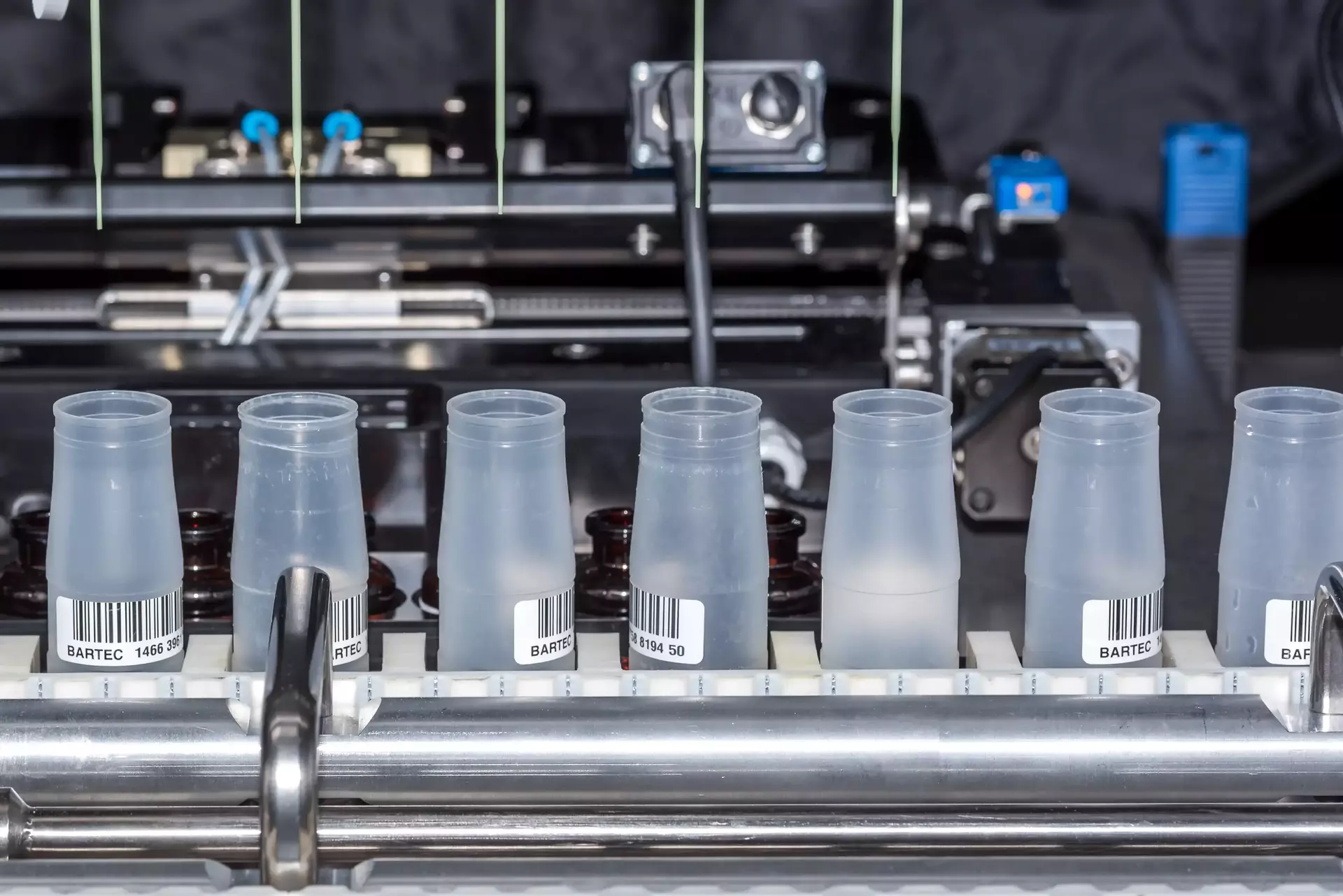

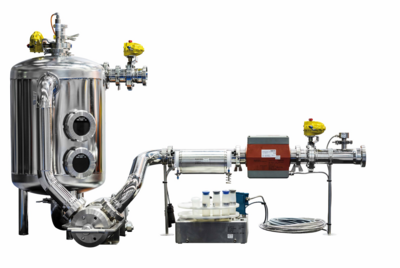

Explosive atmospheres are one of the special challenges facing the beverage industry – not only for alcohol-containing products, but also for the processing of ingredients of other soft drinks. BARTEC solutions have proven themselves for many years in the direct manufacturing process, such as that used in distilleries or soft drinks production, and in accompanying processes such as industrial label/packaging printing or upstream and downstream warehouse and shipping logistics.

Explosive atmospheres also regularly occur during the production and processing of solid foods, for example during flour processing or in various drying processes. Our experts understand the challenges of the food industry and use their decades of experience in explosion protection to ensure that our customers can concentrate on their core competencies. BARTEC stands for safety in the food and beverage industry.